Turnkey water chilling plant for aluminum treatments: needs and solution

Refrigeration systems for the metal oxidative treatment industry often have to meet a peculiar requirement: very low output temperatures. This was no exception to a metal treatment company in the Brescia area, which was served with a true turnkey water chiller system.

Chillers were supplied in conjunction with Frigofluid dry coolers: this is because production lines of the same company may be served by different machinery, with different output temperatures. In this case, the line served by two chillers gives fluid output temperatures (water and glycol) of 7°C.

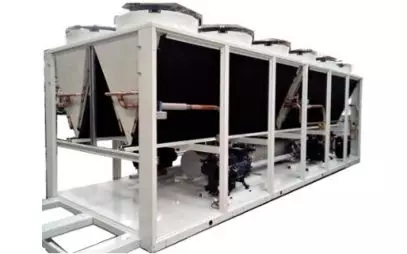

Some technical notes on the industrial chillers supplied: these are two RWE 730/4 ax-ST chillers, equipped with cooling capacity of about 700 kW and four refrigerant gas circuits (R410A, efficient and very safe). Finally, a hydraulic distribution system, nstalled on site with supervision by Frigofluid personnel, is also part of the supply.

A plus of the plant: high energy efficiency, enabled especially by the use of machinery with different technical-functional characteristics depending on the process line supported.

Ask for information