1. Client: semi-finished brass products

Almag – Azienda Lavorazioni Metallurgiche e Affini Gnutti – manufactures brass bars for turning and stamping: it is based in Roncadelle (Brescia) and is now the second largest company in the world for the manufacture of high quality semi-finished bars. Among the sectors its products and services address: construction, automotive, and electromechanics.

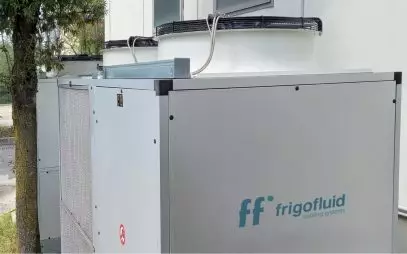

Elasticity, precision and innovation: these are the values that have inspired the company since 1946 in its workings: the last twenty years with the contribution of Frigofluid’s refrigeration technologies.

2. Cooling needs

Production at the Roncadelle plant includes the processing of brass alloys by extrusion process.The company commissioned Frigofluid to provide a refrigeration system for the process liquids (water plus glycol) connected to the presses.

3. Proposed solution

The following were selected:

- two industrial chillers type RWE ax HTA, refrigeration systems suitable for high temperatures and providing high performance;

- and a dry cooler operating with free-cooling mode.

4. Results

The capacity of the unit supplied to Almag reaches 2.7 MW for the press section alone. The temperature of the process fluid output, according to customer requirements, is 20°.

All this with significant energy savings, thanks to the combination with appropriate separate free cooler: quantifiable up to 80% lower than installations without the “free-cooling” device.

Ask for information