For very high outside temperatures. Up to +52°C in standard execution.

ERW ax Liquid Chillers

Air condensation with axial-type fansThese liquid chillers are also suitable for working outdoors and in very high outside temperatures. Depending on the agreed design features, fluid outlet temperatures from -12°C to +30°C can be achieved: adaptability and reliability for all industrial plants.

Fluid output at varying temperatures. From -12°C to +30°C depending on project requirements.

Splash and dust resistance. The IP54 machine protection is especially useful for outdoor installation.

Turnkey solution. A single point of contact throughout the project, possibility of integration with further systems and ancillary plant components.

Quick pay-back. Pre-selection together with the customer, based on his project requirement.

Ready for remote monitoring. A serial port can be coupled to the machine for interface connection with a remote station.

ERW ax chillers: operation

ERW ax systems for industrial refrigeration of process fluids (water, water and glycol) are air-cooled units, using EC (Electronic Control) axial fans.

This range includes a series of models with cooling capacities from 2.1 kWf up to 595 kWf.

Three different versions are provided for different outlet fluid temperature ranges, agreed with the customer during the design phase. The entire range uses refrigerant with GWP 631.

Tell us your needs

Focus: electronic circuit microprocessor and hydraulic circuit

For thermostatting the water (glycol) and displaying the working pressures of the refrigerant gas with the possibility of remote diagnostics; an alphanumeric display communicates the operating ‘status’ of the unit. In multi-compressor machines, the microprocessor rotates the starts of the compressors to balance their working hours.

For different fluid outlet temperatures

The ERW series is specifically designed for applications in high temperature environments. Different variants are developed depending on the design temperature of the fluid outlet.

- ERW ax MT: -12°C to +5°C

- ERW ax HT: +1°C to +25°C

- ERW ax HHT: +15°C and to +30°C

Versions and types of accumulation available

- ERWA ax: with thermally insulated internal storage at atmospheric pressure.

- ERWC ax: with hermetically sealed internal storage. Ensures the possibility of parallel connection with other power packs on the same hydraulic circuit if there is a need to increase cooling capacity at a later time.

- ERWE ax: allows operation in the presence of external accumulation such as: tanks, vats or anything else representing a flywheel of liquid to be cooled external to the central unit.

Ask for information

Series components on all Frigofluid chillers

1. EC (electronic control) Axial Fans

2. Microchannel Condenser

3. Compressors

4. AISI 316 SS Plate Evaporator

5. Storage tank

6. Electronic Microprocessor for the hydraulic and Chilling Systems

EC (electronic control) Axial Fans

As standard over the entire production range. They guarantee high performance at top speed and control in the slowrunning range.

Microchannel Condenser

Featuring a wide exchange surface and subcooling system plus epoxy paint surface treatment as standard.

Compressors

Hermetic systems of “Scroll” type on all models in the catalog.

AISI 316 SS Plate Evaporator

Or tube-nest evaporator. With foam closecell thermal insulation.

Storage tank

In zinc-plated steel featuring close-cell foam insulation and a range of accessories: air exhaust, safety valve, discharge valve, fittings for level control.

Electronic Microprocessor for the hydraulic and Chilling Systems

Allowing control of the (glycol-added) water temperature and display of the chilling gas operating pressure with remote diagnostics possibility: an alpha-numeric display shows the unit’s working status. In the units with more than one compressor, the microprocessor controls their starts on a rotation basis in order to balance their operating hours.

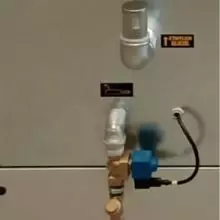

Manual By-Pass

An accessory designed for the function of adjusting the flow rate of water or water/glycol from a hydraulic circuit so as to obtain a working condition suitable for the chiller and its use. This adjustment is carried out by controlling the discharge pressure of the chiller pump.

Expansion Vessel Kit

An accessory designed for the function of containing changes in "hydrostatic" pressure in a type "C" (pressurized) hydraulic circuit due to changes in water and/or water/glycol liquid temperature.

Outdoor Kit

This is an accessory consisting of 3 elements that ensure IP 55 watertightness of the electrical panel and its components for outdoor installation without any canopy or other protection. With OPT 01250 a cover is applied on the electrical box that protects the gasket of the switchboard door.

RTU Modbus

Allows communication of data from our control panels with supervisory and/or other systems through a modbus communication but also OPC UA and PROFINET.

Automatic Loading

Hydraulic system aimed at controlling the filling from water or water/glycol of hydraulic circuits. Consisting of accessories and fittings, it is installed on RW power plants, RAW coolers, and systems in general.

Water Filter

Mechanical filter installed on the water inlet pipe to the chiller (return). The filter usually Y-type can be bronze for sections up to 2" ½ max 3", or spheroidal cast iron flanged for sections 3" and up.

Custom Chiller for a Machinery Manufacturer

Frigofluid is also available for highly customized chillers: this is what a food industry machinery manufacturer also required for a chiller solution capable of working in outdoor environments and with fluid output at temperatures below 0°C.

Read moreTools to help you choose

Preliminary Assessment

Customized Design

Custom Chillers and Turnkey Plants

Resources

Plants and components

Find out all Frigofluid's productsComparing Different Technologies

Find out all the different technologiesFind out more

All technical articlesOur Newsletter

Subscribe to the Frigofluid newsletter: stay up-to-date on technical solutions for industrial refrigeration and cooling and get to know our offer.