Sustainability of Refrigeration and Cooling Systems

Efficiency... aiming at 2050

Also in view of the targets set by the European Commission to be reached by 2050, industrial refrigeration is called upon to do even more for sustainability and the circular economy: natural refrigerants, green technologies 'by default', and technical measures to optimise the use of resources can be good for the environment and customers' investments.

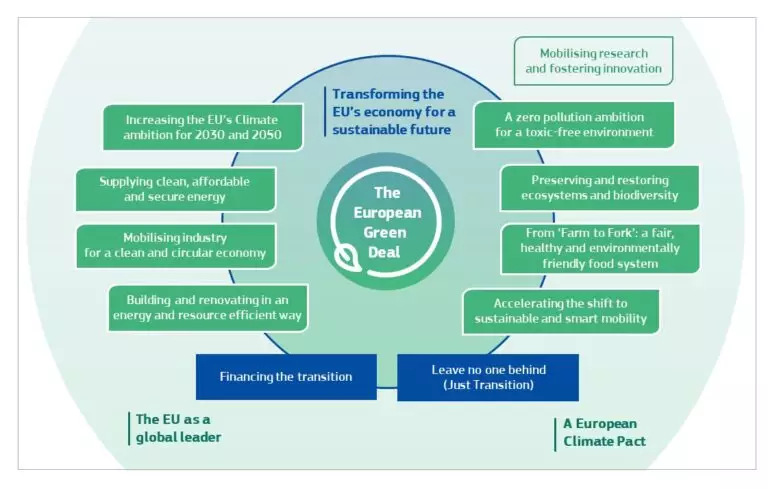

European Green Deal

The European Commission has set the European Union the goal of climate neutrality by 2050.

These are some examples of targets to achieve the goal:

- investment in environmentally friendly technologies,

- introduction of circular economy mechanisms (i.e. a system designed and built to sustain itself),

- decarbonisation of energy.

The companies of the MITA Group, and Frigofluid in particular, are keen to continuously improve their practices in line with these guidelines: how can we make industrial refrigeration and cooling more and more sustainable?

Frigofluid solutions for environmental sustainability

When the aim is to optimise the use of resources, there is no shortage of technologies.

The starting point is judicious selection and design: designing machinery according to the actual environmental characteristics (such as temperatures and climatic peculiarities of the installation area) means starting off on the right foot. The testing and acceptance phase certifies the quality of the work done.

Then there are some technical solutions that focus on environmental sustainability and resource savings.

- Technologies that optimise system operation down to temperature and resource requirements: chillers with free-cooling, dry coolers with adiabatic mechanism: e.g. the RW EFC ax chiller and the PAD-V adiabatic dry cooler.

- Subcooling systems, as an integration of CO2 refrigeration systems, such as Alchemist from MITA Cooling Technologies: the aim is to increase the performance of these systems while maintaining the logic of environmental sustainability.

- A further possibility is to develop a refrigeration system equipped with a chiller, cooling tower and heat exchanger: here too, the aim is to aim for both environmental and economic sustainability, focusing on the different advantages of the three solutions combined with different process lines.

- Remote management in an Industry 4.0 perspective, for real time control of operation and resource utilisation.

Sustainable refrigerants and their management

A major component of cooling chillers are of course refrigerant gases, the management of which is mandatorily delegated to qualified and licensed technical personnel: the aim is to preserve both individual safety and environmental sustainability (in the event of leaks and dispersion into the environment).

Not only have regulations moved to make industrial refrigeration more and more environmentally and health friendly. Research and development throughout the industry is also very active to produce efficient and sustainable gases.

An example of this is the R513a gas, which is efficient and more sustainable than the old HFC gases, and which is becoming more widespread in the industry today (and which Frigofluid installs on some chillers.

The future lies in even greener and, in any case, high-performance solutions.

Joint benefits for the environment and investment

- Models selected according to actual environmental and project conditions: efficiency, less waste.

- Lower water and energy costs through optimised machine operation: including precise parameterisation and remote control.

- Sustainable and efficient chillers, coolers, temperature controllers.

Resources

Plants and components

Find out all Frigofluid's productsComparing Different Technologies

Find out all the different technologiesFind out more

All technical articlesTools to help you choose

Customized Design

Custom Chillers and Turnkey Plants

Our Newsletter

Subscribe to the Frigofluid newsletter: stay up-to-date on technical solutions for industrial refrigeration and cooling and get to know our offer.