Guide to choosing a cooling or temperature control system

A comparison of coolers, chillers and temperature controllers

Do you need to dissipate or add heat to your process fluids? Should the output be higher or lower (and by how much) than the ambient temperature? Is the focus on performance or on saving water and energy? You have at your disposal different types of cooling, refrigeration, thermoregulation systems: you will find your first answers in these boxes... and in us, a contact person always at your disposal.

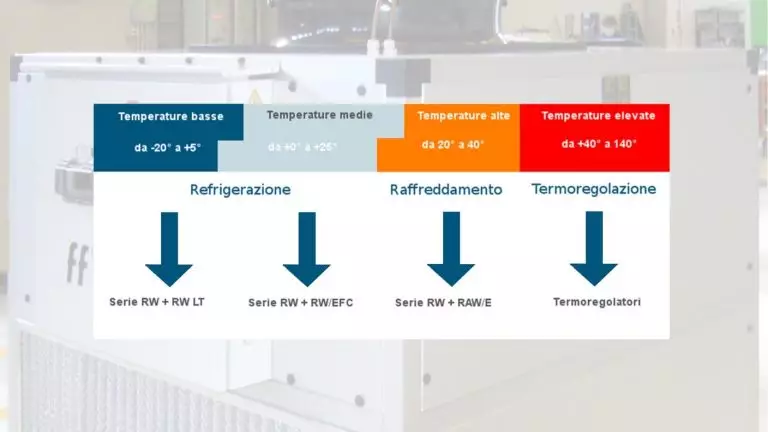

A solution for every temperature

Let us start with the outlet fluid temperatures.

Generally, one speaks of refrigeration when one intends to reach temperatures below that of the environment. Otherwise, any form of heat dissipation is more properly referred to as cooling. All this even though in everyday language there is often no clear distinction between the two.

Thermoregulation is of course a different domain: instead of dissipating heat, thermoregulation units add heat to process fluids in order to make them perform mechanical operations (typically moulding).

The temperatures in the picture opposite are of course indicative and depend to a very large extent on the surrounding environmental conditions. They can, however, give you a rough indication.

Refrigeration, cooling, thermoregulation: what is your need?

Tell us your needs

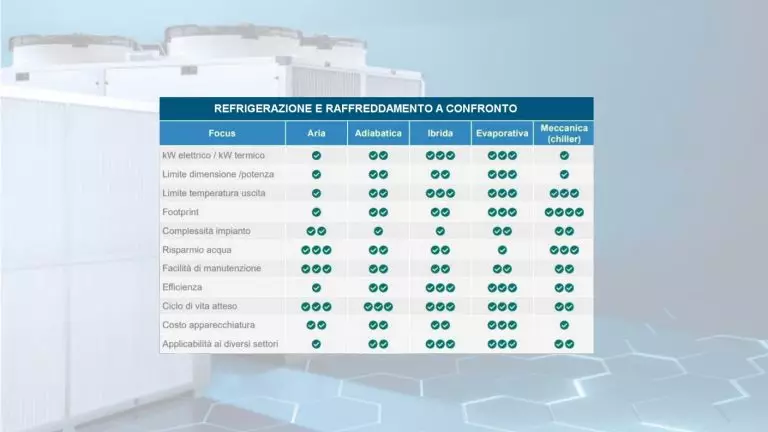

Refrigeration and cooling systems: a quick comparison

The box opposite gives you more information if your need is in the area of heat dissipation from process fluids: you therefore need refrigeration or cooling systems.

Different technologies are available on the market to combine performance needs and resource savings in different ways:

- air (or dry) cooling,

- adiabatic cooling,

- evaporative cooling,

- mechanical cooling or refrigeration (process chillers).

Some concrete examples

What is your main requirement in the area of cooling and heating?

- Very low fluid outlet temperatures, high performance: we are talking about process coolers.

- Medium temperatures and optimisation of resources: adiabatic cooling is the right solution.

- Zero water use, medium-high temperatures: water cooling is the choice for you.

- High performance, low to medium temperatures… and water is a usable resource: ask about evaporative cooling towers, perhaps from MITA Cooling Technologies (a MITA Group company like Frigofluid).

- Heating and maintaining process fluids at high temperatures: this is the purpose of temperature controllers, especially if equipped with auto-tuning.

Not only that.

Do you have to manage a complex industrial plant, or one with several process lines? You may need a turnkey refrigeration system: chiller, cooler, temperature control unit, accessories and sub-supplies.

Discover the components of a turnkey refrigeration systemResources

Plants and components

Find out all Frigofluid's productsComparing Different Technologies

Find out all the different technologiesFind out more

All technical articlesTools to help you choose

Customized Design

Custom Chillers and Turnkey Plants

Our Newsletter

Subscribe to the Frigofluid newsletter: stay up-to-date on technical solutions for industrial refrigeration and cooling and get to know our offer.