Examples of industries: machine tools, hydraulic, EDM, printing and flexographic lamination; presses and brass stamping.

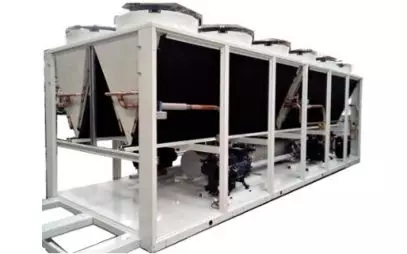

Chillers for Machine Tools and Mechanical Engineering

In the mechanical engineering industry, we have to deal with cooling points at very different temperatures: chillers for machine tools must be designed for the output temperatures required in individual production lines. Temperature control units are often used, and chillers with free-cooling for energy optimisation are certainly a plus.

Main requirements: different cooling points, need for thermoregulation, keeping the fluid at a constant temperature, energy optimisation.

Machine Tool Chillers: printing presses and flexographic lamination

We are referring here to the closed-circuit cooling of calenders and/or rollers in the printing and packaging sector.

The target in this case is represented by production lines that are sometimes complex and have several cooling points at very different temperatures: we go from cooled rollers (never at too low a temperature due to condensation problems) to thermoregulated rollers even above 100°C.

It is not unusual to have thermoregulation units often to avoid the stresses caused by any pressurised water circuit. It should be noted in this regard that cylinders are often tested in water even if they are intended to be thermoregulated with diathermic oil. This practice puts the future operation of the system at risk if the cylinders are not then perfectly dried.

Chillers for hydraulic machines, tools, presses and brass stamping

This is where closed-loop oil cooling of the hydraulic movement of industrial machinery comes into play: a classic application for free-cooling chillers, dry coolers, adiabatic coolers.

Tell us your needs

Chillers for EDM machines tools

We are talking here about the closed-loop cooling of machining centres in precision mechanics. The aim is to maintain the temperature of the dielectric fluid at constant and stable values in order to ensure precision machining in EDM processes.

The cooling temperatures range from 8° C to 15° C, thus through the frequent use of chillers in production islands. Companies with many EDM units installed often decide to centralise the system.

Ask for informationSome Frigofluid projects

Industrial Chillers and Dry Coolers for Almag

There is Frigofluid's signature on the refrigeration of Almag's production processes: an opportunity to strengthen relations with a large company in the Brescia area, recognized worldwide. Two industrial chillers and a dry cooler were supplied to the company.

Read moreLow-Temperature Industrial Chiller for a Biogas Player

The biomass sector is one of the most interesting for its implications related to energy recovery: Frigofluid supplied an industrial chiller to an international broker, with final installation in Colombia.

Read moreSaving Energy with a Turnkey Refrigeration System

A large plastics processing company needed to renew its refrigeration plant in its entirety. During the summer shutdown and the concomitant production stoppage, we built a turnkey refrigeration plant complete with: chillers, adiabatic coolers, heat exchanger, electrical panels and storage tank.

Read moreDo you already know your plant engineering requirements?

Tools to help you choose

Preliminary Assessment

Customized Design

Custom Chillers and Turnkey Plants

Resources

Plants and components

Find out all Frigofluid's productsComparing Different Technologies

Find out all the different technologiesFind out more

All technical articlesOur Newsletter

Subscribe to the Frigofluid newsletter: stay up-to-date on technical solutions for industrial refrigeration and cooling and get to know our offer.