Zero water use. The system cools the fluid solely by the ambient air drawn in.

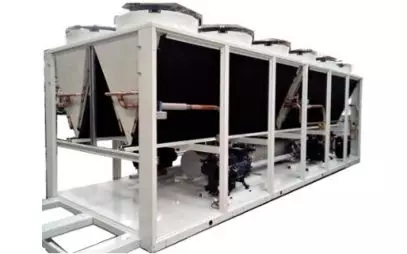

RAW/E Industrial Air Coolers

How to cool process fluids in the total absence of water? By employing industrial air coolers, or “dry coolers,” such as Frigofluid’s RAW/E series: simple, environmentally friendly, low acquisition cost.

For medium to high outlet temperatures. Close to the temperature of the air intake.

Ecological system. Air is the only cooling fluid, energy saving due to high quality materials.

Low acquisition cost. Consequence of the structural simplicity of the system.

Turnkey solution. Single point of contact throughout the project, possibility of integration with additional systems and ancillary plant components.

Prepared for remote monitoring. A serial port can be combined with the machinery for interface connection with remote station.

RAW/E industrial coolers: operation and advantages.

RAW/E liquid coolers (water, water/antifreeze) operate through a closed circuit, consisting of a finned coil crossed in countercurrent by ambient air. Due to the sizing of the coil, it is possible to achieve process fluid temperatures close to the temperature of the intake air.

They are industrial chillers designed for fluids between 0°C up to 70°C, with external temperatures between -10°C and +50°C: cooling powers available as standard from 64 kWf up to 782 kWf, considering a 10°C difference between ambient air and supply water.

“RAW” series chillers are environmentally friendly machines: the fluids used in the cooling process are simply water/antifreeze (fluid to be cooled) and ambient air (cooling fluid). In addition, the use of high quality materials allows the achievement of high efficiency values (ratio of kWf rendered in cooling to kW absorbed in power consumption).

Particular applications that do not allow the addition of antifreeze in the hydraulic circuit find the solution with the installation of the cooler model “RAW / S” that provides manual or automatic emptying of the “battery”.

Ask for informationSome Frigofluid projects

Industrial Chillers and Dry Coolers for Almag

There is Frigofluid's signature on the refrigeration of Almag's production processes: an opportunity to strengthen relations with a large company in the Brescia area, recognized worldwide. Two industrial chillers and a dry cooler were supplied to the company.

Read moreSaving Energy with a Turnkey Refrigeration System

A large plastics processing company needed to renew its refrigeration plant in its entirety. During the summer shutdown and the concomitant production stoppage, we built a turnkey refrigeration plant complete with: chillers, adiabatic coolers, heat exchanger, electrical panels and storage tank.

Read moreWater Refrigeration Plant for Aluminum Treatments

A complete, high-performance water chilling plant: that was the need of a company in the Brescia area active in the processing of semi-finished metal products. Frigofluid supplied three chillers, a dry cooler and the complete installation by drawing on its expertise in the sector and exploiting group synergies. One plus: energy efficiency.

Read moreTools to help you choose

Preliminary Assessment

Customized Design

Custom Chillers and Turnkey Plants

Resources

Plants and components

Find out all Frigofluid's productsComparing Different Technologies

Find out all the different technologiesFind out more

All technical articlesOur Newsletter

Subscribe to the Frigofluid newsletter: stay up-to-date on technical solutions for industrial refrigeration and cooling and get to know our offer.