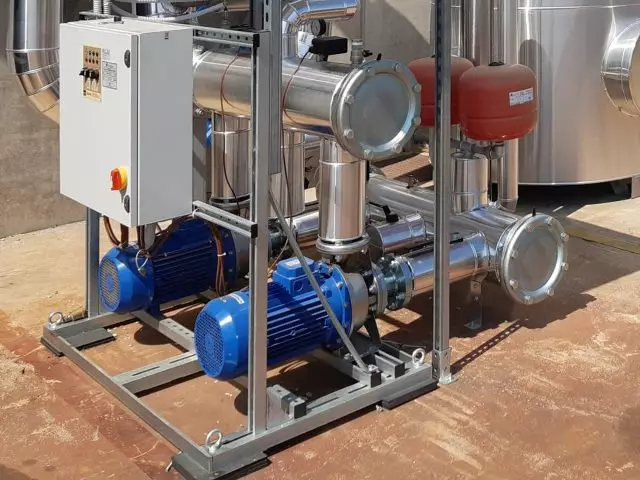

Modular process skid

Frame for easy transportation of the process system (optional).

A refrigeration system is more than a single chiller: heat exchangers, hydraulic connections, additional cooling devices also come into play to support your production process.

Modular process skid

Frame for easy transportation of the process system (optional).

Chiller

Water- or gas-condensed process liquid refrigeration system. Outlet temperatures down to -20° C and/or below ambient air. Operation also possible at outside temperatures up to 52°. Remote monitoring as standard. Frigofluid design and production.

Coolers

Sometimes additional cooling systems can contribute to further heat dissipation in an optimal way: these are generally dry coolers (air cooled) or adiabatic dry coolers (using water and electricity that can be optimized according to the outside temperature). From MITA Cooling Technologies Group company.

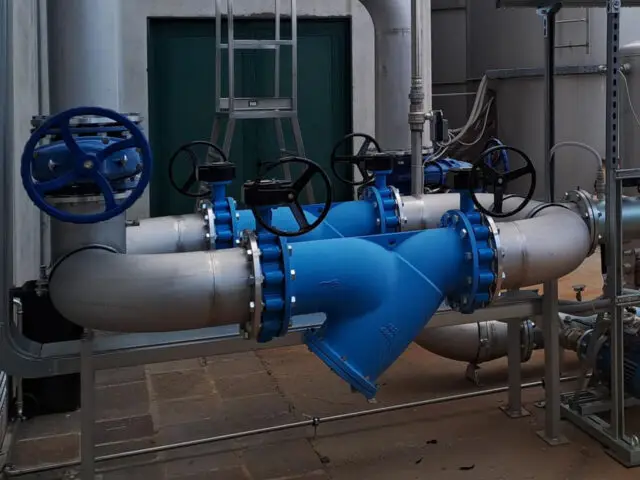

Hydraulic connections (Piping)

To convey primary and secondary circuit (i.e., process and cooling) fluids between different systems in the plant.

Inertial storage tank

For possible containing of refrigerated process liquid.

Pumping group

To keep the whole hydraulic circuit always at the right pressure.

Hydraulic automations

Valve system, hydraulic loading, pump blocking kit.

Recovery water disposal

For equalization of the hydraulic system.

Water chemicals

The circuit water must always be treated to avoid clogging.

Control panels and Industry 4.0

Systems for optimization and automation of water and energy on all plant components. Frigofluid chillers are certified for remote monitoring from an Industry 4.0 perspective.

Thermoregulation units

The main production plant needs to keep process fluids at the right temperature: industrial Frigofluid temperature controllers are used for this purpose.

A single point of contact Proven solutions and manufacturer's guarantee of results.

Efficiency and optimal resource use Frigofluid solutions are selected to suit the individual plant through advanced software.

Advanced consulting The value of a personal consultant, at the client's side for plant management needs.

Quick pay-back Pre-selection together with the client, based on the client's project requirement.

Assistance throughout the project Advanced design, installation assistance, ongoing support.

Remote monitoring The plant is transformed to Industry 4.0: performance, consumption, maintenance at the click of a button.

Relying on a single point of contact for all components, and related support activities, saves time and cuts costs: we propose to be that point of contact for you, making use of MITA Group participation and experienced subcontractors to select the best instrumentation on the market.

Tell us your needsLet us ask the questions and find out together what you need: peculiarities of your production process in relation to heat dissipation, fluid outlet temperatures, technical specifics to be taken into account at the design stage.

In many cases, an on-site visit is helpful in confirming or deepening the elements that emerged during the initial interview. A quick and decisive on-site presence is often appreciated by many users.

The discussion between Frigofluid and your staff continues with our business proposal: we can work out the details and reshape the proposal together.

Over the years, Frigofluid has selected a number of reliable partners for individual components to complement its own custom solutions and coolers from MITA Cooling Technologies (a company part of the MITA Group).

The service includes on-site transportation of both chillers and ancillary components, from Frigofluid or other subcontractors. You will not have to worry about plumbing connections.

The components, one by one, are tested at the site of their installation and at standard operation: correctness of installation, performance, operation of the electronic part (control panels and possible remote management).

At this stage, Frigofluid chillers and MITA Cooling Technologies coolers have already been tested at the production site and tested after detailed verifications.

The system is now at the service of your industrial process. Until the time of periodic maintenance, you can take care of the main production line and your core business.

Chillers, coolers, temperature controllers, accessories and installation services for an Italian designer objects company.

Read moreA complete, high-performance water chilling plant: that was the need of a company in the Brescia area active in the processing of semi-finished metal products. Frigofluid supplied three chillers, a dry cooler and the complete installation by drawing on its expertise in the sector and exploiting group synergies. One plus: energy efficiency.

Read moreA large plastics processing company needed to renew its refrigeration plant in its entirety. During the summer shutdown and the concomitant production stoppage, we built a turnkey refrigeration plant complete with: chillers, adiabatic coolers, heat exchanger, electrical panels and storage tank.

Read moreSubscribe to the Frigofluid newsletter: stay up-to-date on technical solutions for industrial refrigeration and cooling and get to know our offer.