Turnkey refrigeration for a historic design brand

From the refrigeration of the moulding circuit to the closed-loop cooling of process oils and the management of heat in mould fluids: Frigofluid has managed the processes of a manufacturer of high-design plastic containers with its refrigeration, cooling and temperature control systems. Not only that. Together with the turnkey refrigeration system, pump units, hydraulic accessories, control panels (also for remote management) and storage tanks were also supplied.

For each process line, the best technical solution was studied and designed, based on the peculiarities and different needs for heat disposal or management: this also means optimising the use of water and energy, with considerable savings of these resources.

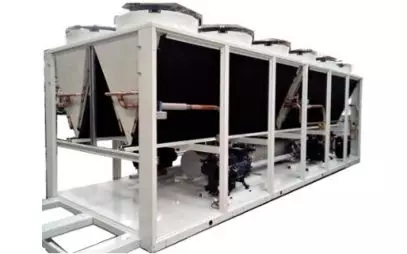

For the mould circuit, a need for an outlet fluid temperature (water) of 13°C was evaluated, with an estimated cooling capacity of 260 kWf: characteristics that led to the use of a RWE 408/4 ax-ST series refrigeration unit: electronically controlled fans, remote monitoring, integration with an external stainless steel storage tank (supplied by Frigofluid together with the integrated system).

The oil circuit on the other hand had an estimated cooling capacity of 330 kWf, with an outlet fluid temperature (water and glycol) of ‘only’ 32°C. An adiabatic cooler PAD-V S 3/4 Q was therefore selected, which is suitable for medium temperatures and with which it is possible to switch operating modes: from ‘standard’ air cooling to adiabatic pre-cooling.

The same process optimisation argument applies for mould temperature control. Three different units were selected:

- temperature controller FTT09-110DC-pm,

- temperature controller FTT09-090PD-pm,

- temperature controller FT12-110DC-pm.

DC machines not only allow heat to be injected into the system, but also stabilise the fluid at high temperatures and/or even very close to the temperature of the cooling source, thus allowing the most cost-effective cooling system in terms of energy savings: this enables a precision of the moulding process that is unrivalled. All three temperature controllers are also equipped with a high head pump, to increase pressure in the event of high pressure drops, and with the possibility for the PD machine to work under both pressure and vacuum (to overcome fluid losses in the production process). Finally, the FTT temperature controllers are equipped with a touch-screen panel and Ethernet communication protocol.

Ask for information