Industrial chiller for biogas plant: need and solution

The production of biogas is one of the most promising areas in the field of renewable resources: it starts with the transformation of biomass (such as agricultural and animal residues) through a process called ‘anaerobic digestion’. Biogas has a high calorific value, but it must be cooled down to around 5°C for its exploitation: this is where industrial chiller systems come into play, a technology also supplied to Frigofluid’s customer plant operator.

We are talking about a supplier of technology for biogas production and cogeneration that works specifically for the purification and cleaning of the gas: a fundamental phase in making this resource profitable. It is precisely in the biogas pre-treatment phase that the Frigofluid chillers supplied come into play: the biogas must be cooled down to a temperature of around 5°C. Specifically, the company needed to bring the temperature of the fluid used (water and glycol) down to 0°C in order to carry out production processes.

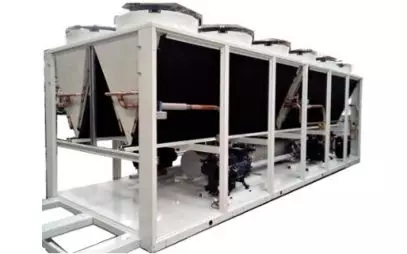

They opted for a RWC 30 ax-LT chiller or liquid chiller, equipped with hermetic internal storage (with the possibility of connecting other plants in parallel): this was due to the plant’s space management requirements. The ‘LT’ version allows the very low temperatures required for the process.

The final installation of the chiller supplied to the plant engineer took place in a production plant in Colombia.

Ask for information