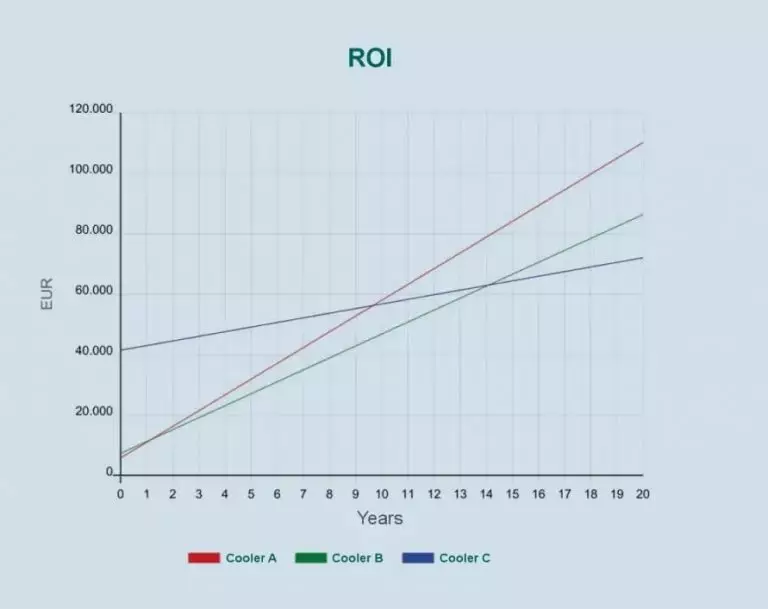

Return on investment in industrial refrigeration

The benefits of correct selection

Although there is no perfect industrial refrigeration or cooling system for every need, careful selection allows for long-term savings. Reduced maintenance, minimised resource usage and system efficiency depend on the fundamental initial steps.

How to recognise the lowest product life-cycle cost

As in other areas, in industrial refrigeration the most cost-effective acquisition… is conscious acquisition.

Knowing your plant and environmental needs, as well as the availability of resources (water and energy), means selecting the best refrigeration, cooling or temperature control system: both in terms of efficiency and effectiveness, and in terms of return on investment.

There are different solutions for different needs: you can discover the key ones by reading our Selection Guidelines.

Tell us your needs

Saving in the long run: the preconditions

A properly sized industrial chiller or cooler, based on project requirements, ensures performance and enables savings in CAPEX and OPEX.

Testing and commissioning of all its components also enables a number of benefits in terms of return on investment:

- simple (and minimal) maintenance,

- optimal resource utilization,

- efficiency and performance.

Resources

Plants and components

Find out all Frigofluid's productsComparing Different Technologies

Find out all the different technologiesFind out more

All technical articlesTools to help you choose

Customized Design

Custom Chillers and Turnkey Plants

Our Newsletter

Subscribe to the Frigofluid newsletter: stay up-to-date on technical solutions for industrial refrigeration and cooling and get to know our offer.