Examples of industries: production of steel, alloys and semi-finished products, aluminium and zamak die-casting, galvanic treatments, metal galvanising, anodic oxidation of aluminium.

Chillers for Metalworking

This is a classic industrial refrigeration application: often, metalworking chillers operate on several production lines in the same plant, with different temperature ranges and different outlet fluid temperatures. It is not infrequent that a complete cooling plant is also supplemented by temperature control units: these are useful for keeping the temperatures of the process fluids constant, according to preset values.

Main requirements: high temperature differences, several production lines to be cooled in the same plant.

Chillers for steel mills and foundries

Chillers for steelworks and foundries are particularly involved in the cooling of induction furnaces, transformer rooms, hydraulic handling, AHUs, etc.

Chiller units are thus part of the production of steel, alloys and semi-finished products.

In addition to the heat dissipation part, we must not forget the contribution made by temperature control units to control and keep even high temperatures constant in various heating elements, according to predetermined values. Such temperature control units are often present in complete turnkey refrigeration plants.

Tell us your needs

Turnkey Industrial Refrigeration Plants

A refrigeration system is more than a single chiller: heat exchangers, hydraulic connections, additional cooling devices also come into play to support your production process.

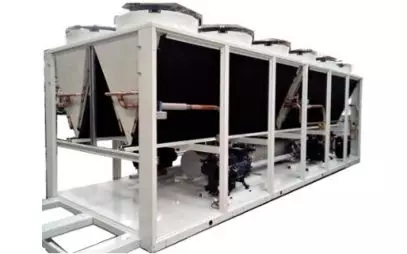

RW / EFC ax Liquid Free-Cooling Chiller

The secret of this system is the combination of the refrigeration section and the free-cooling section depending on the time of day and year: the first mode allowed by these liquid chillers takes advantage of the normal operation of a refrigeration circuit, the second allows cold outside air to be directly conveyed to the fluid to be cooled: maximum efficiency, minimum energy use due to the clear separation between the two sections.

PAD-V Adiabatic Cooler Condenser

Adiabatic liquid coolers and gas condensers PAD-V series are offered where the focus is particularly on rational use of water and energy thanks to a dual operating principle, during hot and cold seasons, and thanks to the control panel that optimizes system operating parameters.

Some Frigofluid projects

Water Refrigeration Plant for Aluminum Treatments

A complete, high-performance water chilling plant: that was the need of a company in the Brescia area active in the processing of semi-finished metal products. Frigofluid supplied three chillers, a dry cooler and the complete installation by drawing on its expertise in the sector and exploiting group synergies. One plus: energy efficiency.

Read moreIndustrial Chillers and Dry Coolers for Almag

There is Frigofluid's signature on the refrigeration of Almag's production processes: an opportunity to strengthen relations with a large company in the Brescia area, recognized worldwide. Two industrial chillers and a dry cooler were supplied to the company.

Read moreDo you already know your plant engineering requirements?

Tools to help you choose

Preliminary Assessment

Customized Design

Custom Chillers and Turnkey Plants

Our Newsletter

Subscribe to the Frigofluid newsletter: stay up-to-date on technical solutions for industrial refrigeration and cooling and get to know our offer.