Ease of use. Thanks to the adjustable touch-screen control panel.

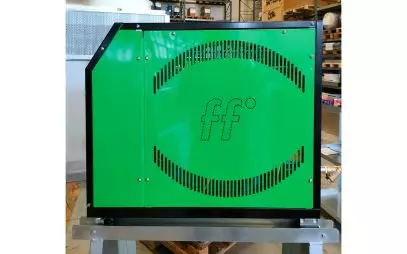

FTT DC Water Thermoregulator

High temperatures, kept stable over time: FTT DC water temperature controllers take advantage of the principle of direct cooling by integrating with external water sources for long self-stabilization to benefit industrial processes. All with great ease of use, thanks to the touch-screen control panel.

Excellent temperature stabilization. Possible through direct cooling function, consequent to classical thermoregulation (water integration with external sources).

High pressure. Models with oversized pump, suitable for users with high pressure drops.

Reduced resource utilization. Through the process of self-stabilization.

Soluzione chiavi in mano. Single point of contact throughout the project, possibility of integration with additional systems and ancillary plant components.

Prepared for remote monitoring. A serial port can be combined with the machinery for interface connection with remote station.

For high temperatures... and stable over time

Often the main critical issue for molding industries is not achieving the temperatures needed for their processes, but maintaining them over time. Hence the usefulness of temperature control units that not only send the fluids needed to do the job up to temperature, but are capable of subsequent self-tuning.

This is the way FTT DC water temperature controllers operate, which wrap direct cooling to stabilize fluid grades after the desired temperature has been reached. This requires integration with a source of cooled water: a simple well or a chiller or cooling system (chiller or dry cooler). Our engineers are available to determine which cooling solution is the most effective and economical.

Not only that. The management of these successive heating-cooling steps is easier when done with a touch screen: a feature with which FTT DC temperature controllers are equipped.

Units in the FTT category are specially designed to condition molds and cylinders. Some examples of industries served: plastics and rubber molding, extrusion, paper converting industry.

Some Frigofluid projects

Process Thermoregulation for a Food Manufacturer in Chile

We have supplied a confectionery manufacturer in Chile with a temperature control unit FT09-110DC-pm: output fluid at 110°C stable over time.

Read moreManufacturing Brand chooses Frigofluid Turnkey Refrigeration Systems

Chillers, coolers, temperature controllers, accessories and installation services for an Italian designer objects company.

Read moreTools to help you choose

Preliminary Assessment

Customized Design

Custom Chillers and Turnkey Plants

Resources

Plants and components

Find out all Frigofluid's productsComparing Different Technologies

Find out all the different technologiesFind out more

All technical articlesOur Newsletter

Subscribe to the Frigofluid newsletter: stay up-to-date on technical solutions for industrial refrigeration and cooling and get to know our offer.