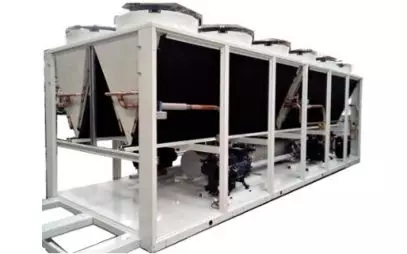

The custom chiller designed by Frigofluid

High performance, for fluid temperatures below 0°C, and resistance in outdoor environments: these were the main demands of a juice company that made it opt for a custom chiller. Thus, with technical-functional features beyond the catalog and strongly focused on the customer’s design needs.

The Frigofluid chiller supplied to the client, the Italian headquarters of an American multinational, was to cool food processing machinery.

Conceptually, the machine designed and installed by Frigofluid is a combination of three different cooling chillers:

- RW CW chillers, water-cooled machinery and thus endowed with high performance;

- ERW chillers, which are suitable for outdoor environments due to their IP54 rating (for dust and splash protection);

- and RW ax LT chillers, good for low outlet fluid temperatures (in this case water and glycol).

Power requirements: 8.1 kW. Water and glycol outlet: -2°C.

Ask for information