1. chillers for agribusiness: precise temperature control

When food and beverage production is at stake, the first requirement is the precise control of production processes: including therefore the fluid outlet temperatures allowed by a chiller. The same request came from an installer of our client, who needed to supply a large Senegalese agribusiness company with a chiller for a production site in Dakar.

The player we served produces sauces and finished tomato paste products.

After an evaluation of the project requirements, they definitely opted for an air chiller instead of a water chiller (given, of course, the scarcity of the water resource in the installation area).

2. Temperatures and cooling capacity

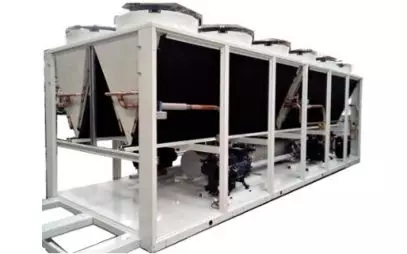

In agreement with the customer, a RW ax series refrigeration system was selected as an alternative to an ERW chiller (for extreme temperatures), judged to be sufficient for high ambient temperatures. given the spatial configuration of the production facility, it was possible to install an external storage tank.

The cooling capacity used places the selected agri-food chiller in the medium-high range of the RW ax series: however, thanks to the electronically controlled motor-fan unit, it is possible to modulate the operating parameters and optimize energy use.

Ask for information