Different needs, different solutions: there is no perfect refrigeration and cooling technology. For process temperatures far below room temperature, or even below 0°C, one can rely on chillers. If, on the other hand, the temperature of the outgoing fluid remains around 30°C, an adiabatic cooling system can support in achieving the right performance with high water and energy optimisation.

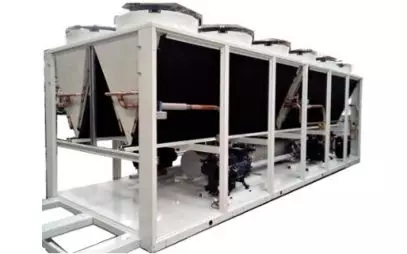

The need of the Varese-based company, a manufacturer of plastic shower components, was the cooling of moulds and presses: the output fluid (water and glycol) must not exceed 32°C, which made management opt for an adiabatic dry cooler, model PAD-V S 1/4 T. Power 100 kW, an electronically controlled fan.

The main plus of the PAD-V adiabatic dry cooler lies in the automatable modulation of the

- dry mode during cold periods of the day and year (like a standard industrial dry cooler)

- and adiabatic mode, with the cooling air pre-cooled through short wetting cycles.

Naturally, this allows optimisation of pre-cooling water and energy for the fan-motor unit.

Ask for information