Industrial chillers for waste water treatment: need and solution

In many cases, the request for refrigeration support comes not from the end-user, but from an intermediate stakeholder in the supply chain: for example, the international plant operator, active for some 150 years, who requested industrial chillers for a municipal wastewater treatment plant in Veneto.

The request concerned the extension and modernisation of two process lines of the plant: the water reuse line and the ozonation line within the tertiary treatment section. In the latter case, it was a matter of a true regulatory upgrade.

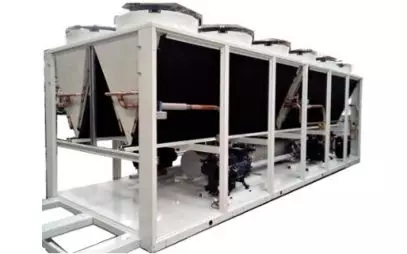

It was decided to select two chiller chillers model RWE 624/4 ax-ST: it was therefore assessed that both process lines would need equivalent equipment in terms of functionality and cooling capacity. The two systems are each equipped with four refrigerant gas circuits (R410A), work with air and are fitted with electronically controlled axial fans: the latter feature allows optimisation of the use of the resource employed.

RWE chillers operate in the presence of external accumulation: tanks, vats or other components that can receive, externally to the plant, the liquid to be cooled. This configuration is possible when available space makes it possible.

Ask for information