Water-cooled chiller: advantages

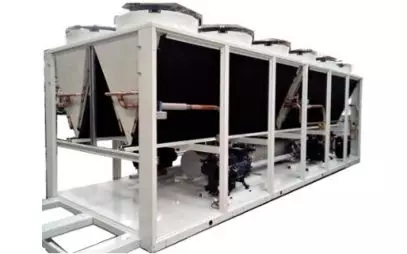

Compression chillers can be divided into two ‘families’: air-cooled and water-cooled. The former use only air and electricity as resources, but may have lower performance than the latter (other parameters being equal). A water-cooled industrial chiller is therefore to be preferred when the focus is on performance and the use of this resource is not a problem for the plant and installation area.

This was also the main interest of a large Italian oil & gas group, active in the production of technical and industrial gases: the specific need concerned the refrigeration of an oxygen production plant.

Together with the installation company, which oversaw the project, a RRWE 10-35 CW ST series water chiller was selected. The machine can be integrated with foreign storage. Cooling capacity: approx. 10 kWf.

Ask for information